Analysis Services

ITR’s Predictive Analytics

ITR’s core business is helping companies design, implement, and improve PdM processes through the use of predictive technologies. By applying an overall process and system approach, organizations ensure PdM activities are aligned with process objectives and limited resources are put to the best use.

VIBRATION & ULTRASONICS ANALYSIS

For many organizations, vibration analysis is the cornerstone of their predictive maintenance (PdM) efforts and reliability process. Of all PdM technologies, vibration analysis often provides the greatest ROI because it is the most comprehensive and most precise. The technology is ideal for many electro-mechanical assets, especially ones experiencing varying operating conditions.

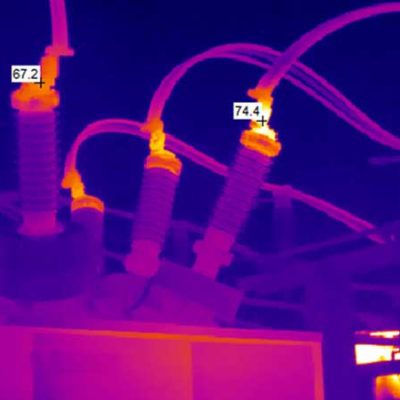

INFRARED THERMOGRAPHY

Infrared (IR) thermography is a non-destructive testing method used to measure thermal gradients in energy emitted by electrical and mechanical systems. From these gradients, competent thermographers identify variations in energy emissions that are traceable to potential asset failure modes. IR emissions often enable analysts to identify problems that are concerns otherwise undetectable using visual or mechanical inspections

MOTION AMPLIFICATION

Motion Amplification is a video processing algorithm that detects subtle motion then amplifies that motion to a level visible with the naked eye which enhances the understanding of the components and interrelationships creating the motion. Motion Amplification is one more tool in ITR’s process and sytem approach to effective, affordable, proven PdM success.

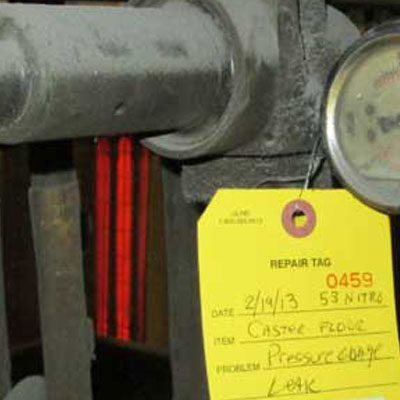

FLUID SAMPLING & ANALYSIS

Lubrication analysis is a non-destructive test used to assess the condition of lubricants or power transmission (hydraulic) fluids and determine the type and amount of contamination present. Because of the criticality of these types of fluids to industrial operations, fluids analysis trending over time is one of the most powerful predictive tools for identifying potential failures. Fluids analysis looks for three basic categories of elements affecting the lubrication effectiveness: wear metals, contaminants, and additives.

Periodic monitoring may prolong fluid life and identify elements that may indicate component or lubricant degradation. Common fluid tests include: elemental spectroscopy, viscosity, acid number, FT-IR, base number, particle count, shape analysis and water analysis.

ULTRASOUND EMISSION MONITORING & ANALYSIS

One benefit ultrasound emission testing offers over many other PdM technologies is that direct contact is not always required and skilled testing professionals can scan large areas quickly from safe locations, in some cases, remotely. For electrical systems, ultrasonic testing is often an ideal technology when used in conjunction with IR thermography as together, the spectrum of potential failure modes is expanded exponentially.

ELECTRIC MOTOR CIRCUIT TESTING AND ANALYSIS

Studies by motor manufacturers indicate that 60% of electrical failures in motors begin as winding to winding shorts. Interturn shorts occur as insulation weakens and degrades due to temperature, voltage surges, mechanical damage during rewinding, motion, moisture and contamination. This degradation occurs in stages which may not be evident as a loss of motor performance.

ITR motor testing and analysis service includes resistance checks, surge tests, winding comparisons, and hipot tests to assess and advise the customer of the electrical condition of motors.

Avoid costly and unnecessary time-based motor rewindings, and Identify potential motor issues prior to catastrophic failure.